Service Hotline

15176609566

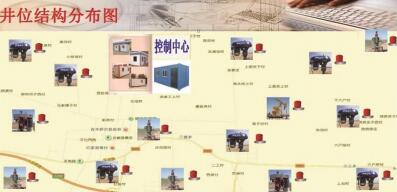

The remote intelligent frequency conversion control system is designed and developed by our company according to the working conditions of oil and gas fields, which can effectively meet the actual use needs of users and is an effective auxiliary tool for engineering and technical personnel.

Performance advantage:

1. All the internal hardware uses ABB components (vector twister converter ACS550), human-computer interaction uses touch computer display, and data acquisition uses American MPLAB digital chip.

2, with display current, voltage, frequency, torque, speed, fault display parameters, equipped with liquid level automatic monitoring device, realize the function of automatically adjusting pump speed according to the sinking degree, remote start and stop, remote data transmission;

3, the cabinet body is made of 2m m high quality steel plate, rust prevention and anti-corrosion treatment, surface spray; It has the functions of ventilation, dustproof, heat preservation, lifting hook, support (40cm high), heat dissipation and rain prevention. Four-layer configuration, cabinet door without electrical connection.

4. The control cabinet can receive and store the torque and load data transmitted by the torsional instrument in real time, and do not use the instrument to detect regularly; Wellhead oil pressure, casing pressure and flow rate can also be transmitted to the control cabinet through sensors.

5. Remote real-time transmission of production data can be realized regardless of signal area, without interruption or loss of data. 6. Host computer matches intelligent well selection software, working condition diagnosis, digital equipment memory and other functions.