At the initial stage of oilfield exploitation, oil reservoirs often have large energy, and oil can flow from underground to the ground depending on energy. With the continuous consumption of reservoir energy, when the reservoir energy is not enough to make the oil flow to the surface along the wellbore by its own energy, it must be artificially supplemented to make the oil to the surface, which is collectively referred to as artificial lifting.

In this lesson, we will introduce the meaning of artificial lifting, the composition and functions of the mechanical mining electric pump system and the installation process of the offshore electric submersible pump unit.

Overview of Oilmooc VC No.13 artificial lifting technology

Artificial lifting means artificial technology to lift oil and gas from the bottom of the well to the ground

Artificial lifting is to artificially supplement energy to the bottom hole, maintain a low bottom hole production pressure, and enable the formation to output the required reservoir fluid.

For oil wells that cannot flow out at the beginning due to late flowing out or geological characteristics of the formation, we must install a suitable artificial lifting device to carry out oil and gas production.

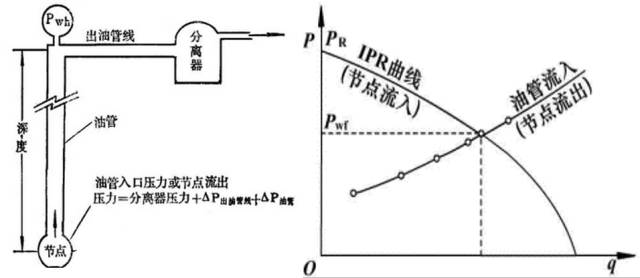

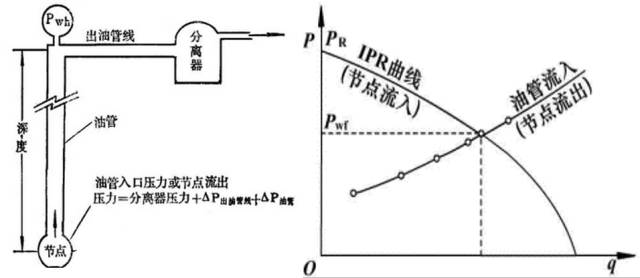

Node analysis diagram with well bottom as node

As shown in the above figure, with the continuous development of the oil field, the formation energy is gradually consumed, and the IPR curve moves downward. At this time, it is necessary to install artificial lifting device and move down the tubing inflow curve to obtain lower bottomhole flow pressure, so as to maintain production.

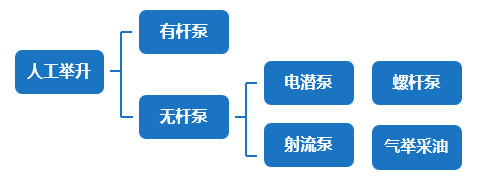

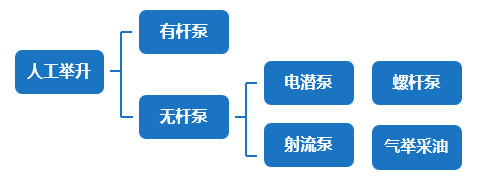

Artificial lift type rod pump and rodless pump production technology

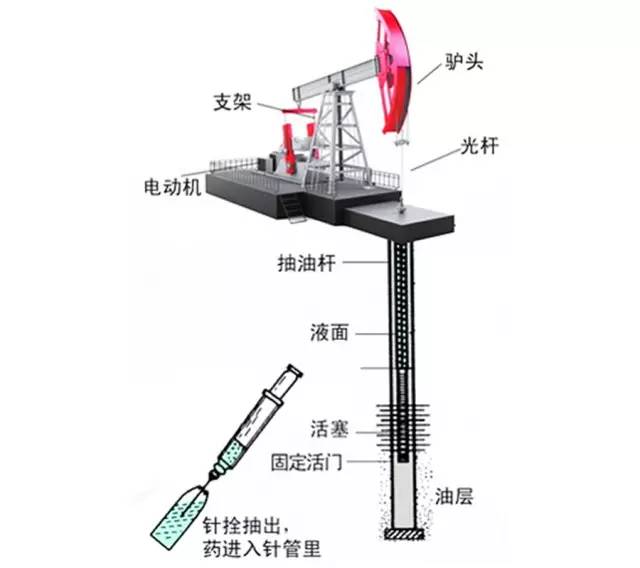

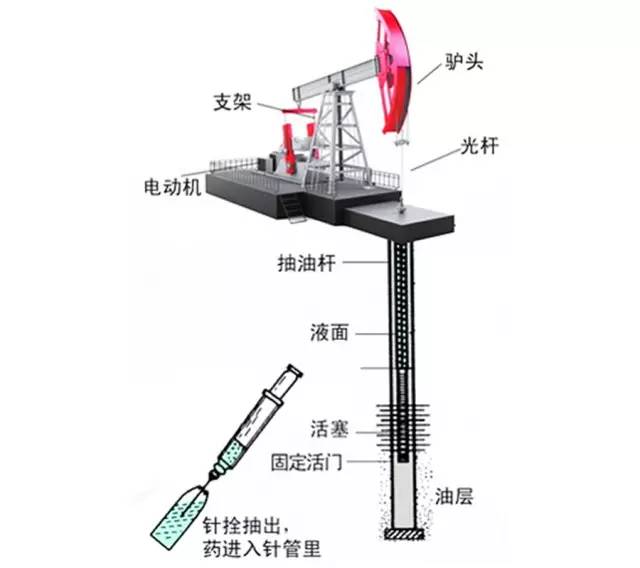

Sucker rod pump oil production mainly refers to the pumping mode driven by the reciprocating movement of sucker rod.

Rodless pumping refers to the use of cables or high-pressure liquid to transfer energy for pumping. It mainly includes electric submersible pump, screw pump, hydraulic jet, gas lift oil production, etc.

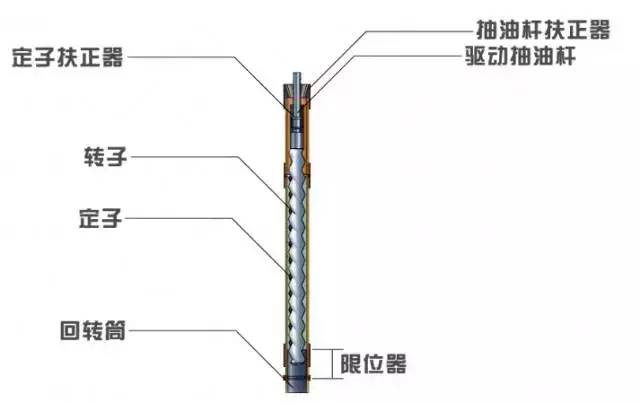

Schematic diagram of sucker rod pump production

Common lifting types of electric submersible pump and screw pump in Bohai mining area

The common lifting types in Bohai mining area are electric submersible pump and screw pump technology.

Electric submersible pump technology is an oil production technology that puts centrifugal pump and motor into the well and lifts oil to the surface.

The electric submersible pump is a kind of electric centrifugal pump which is connected by multistage vane guide wheels in series, and its working principle is similar to that of ordinary centrifugal pump.

Electric submersible pump assembly drawing

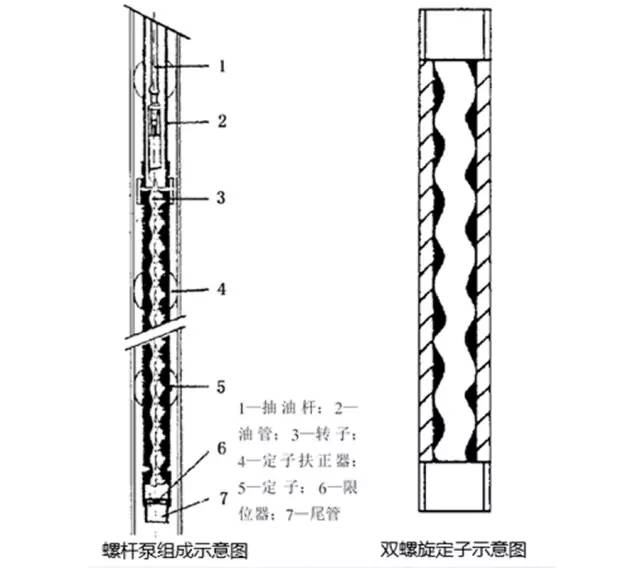

Screw pump is a new type of oil extraction device based on the rotary displacement produced by liquid.

Working principle of screw pump

Screw pump is a positive displacement pump, which is composed of two mutually meshed screws, namely rotor and stator, or screw or bushing. With the rotation of the rotor, the cavity in the seal moves from the suction end of the pump to the discharge end. When the screw pump works in the downhole fluid, the downhole fluid is pressed into the open chamber of the screw pump under the pressure of the pump inlet, and is continuously discharged to the pump outlet with the axial movement of the chamber.

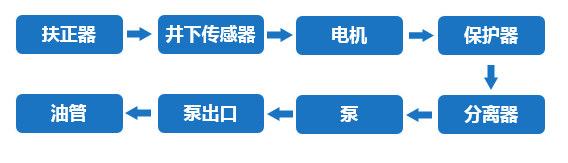

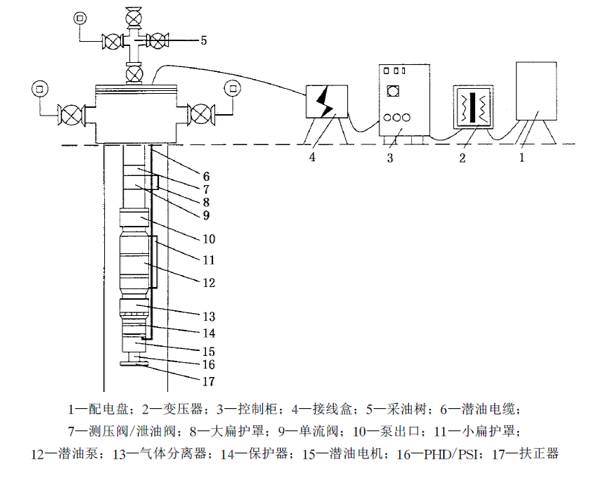

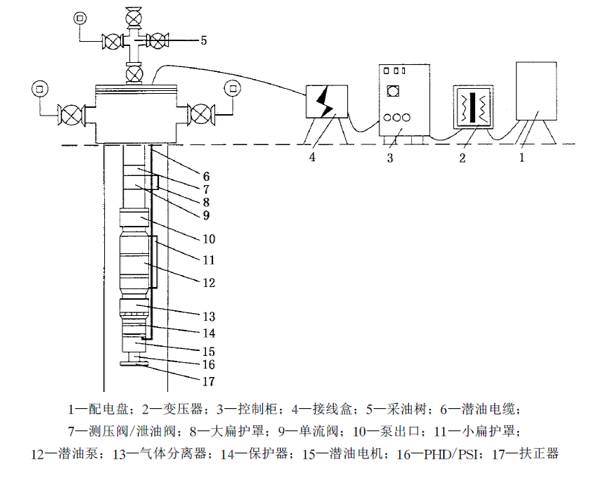

The electric submersible pump production system consists of underground and surface parts

The electric submersible pump production system is composed of underground and surface parts.

The downhole part of electric submersible pump is mainly composed of motor, submersible pump, protector, separator, pressure measuring device, power cable, single flow valve, pressure measuring valve/oil drain valve, centralizer and cable shield.

The ground part of the electric submersible pump is composed of distribution board, transformer, control cabinet or frequency converter, junction box and Christmas tree wellhead. Some special oilfields are also equipped with frequency converter centralized switching control cabinet.

Schematic diagram of electric submersible pump system

1 Motor

The electric submersible pump motor, also known as the submersible motor, is the prime mover of the electric submersible pump unit, generally located at the bottom. The working principle is the same as the ordinary three-phase asynchronous motor, which converts electrical energy into mechanical energy.

2 Submersible pump

The submersible pump is a multistage centrifugal pump. The electric submersible pump is divided into sections and divided into stages. Each stage is a centrifugal pump.

3 Protector

It is unique to electric submersible pump. It is located between the motor and the gas separator. The upper end is connected with the separator and the lower end is connected with the motor to protect the motor.

4 Gas separator

The gas separator, also called oil-gas separator, is located at the lower end of the submersible pump and is the inlet of the pump. Its function is to separate the free gas from the oil well production fluid.

5 Pressure measuring device

There are two types of pressure measuring systems for electric submersible pump wells, one is electronic and the other is mechanical. It is mainly used to monitor the fluid supply and motor operating temperature of oil wells.

6 Single flow valve

Its main function is to maintain a sufficiently high return pressure, so that the pump can work at the rated point quickly after starting; Prevent the fluid above the pump from falling back and causing the unit to trip in reverse direction after the pump is stopped; It is convenient for production string sealing inspection.

7 Oil drain valve

It is the discharge port of fluid in the tubing when lifting the string during the pump inspection operation to reduce the load of the workover rig and prevent the well fluid from polluting the platform deck and environment.

8 The power cable motor is connected with the ground power supply and control system to transmit the power cable and PSI/PHD signal.

9 Cable shield The cable shield and the cable are fixed on the outer surface of the oil pipe by binding to prevent the cable from mechanical damage in the process of running into the well.

10 Centralizer

Centralizer is mainly used for inclined shaft, which is located at the tail of the motor to center the motor, so that the external overcurrent of the motor is uniform, and the heat dissipation environment is good, so as to prevent the motor from being damaged due to local high temperature.

Screw pump production system consists of surface-driven screw pump and submersible motor-driven screw pump

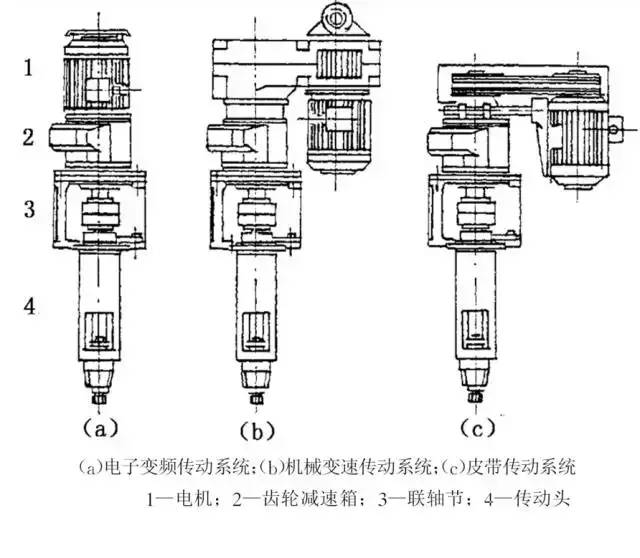

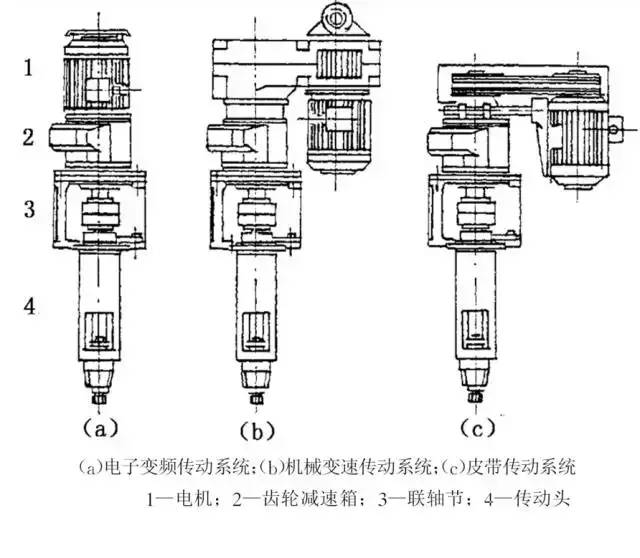

Ground driven screw pump

The power unit of the surface-driven screw pump is on the ground, and its prime mover is usually the motor. The rotation of the motor is transmitted to the drive head above the wellhead through different transmission methods, and then transmitted to the rotor of the downhole screw pump through the sucker rod for pumping. Therefore, it is also composed of ground and underground systems.

Ground system

It includes transmission system, transmission head and coupling assembly.

螺杆泵的(of)傳動系統組成示意圖

The basic composition of submersible motor driven screw pump is basically similar to that of electric submersible pump. All moving parts are underground. The underground pumping system is composed of submersible motor, gear reducer, protector, flexible shaft, submersible screw pump and suction port. The string accessories such as oil drain valve and pressure measuring valve and the ground system are the same as the electric submersible pump.

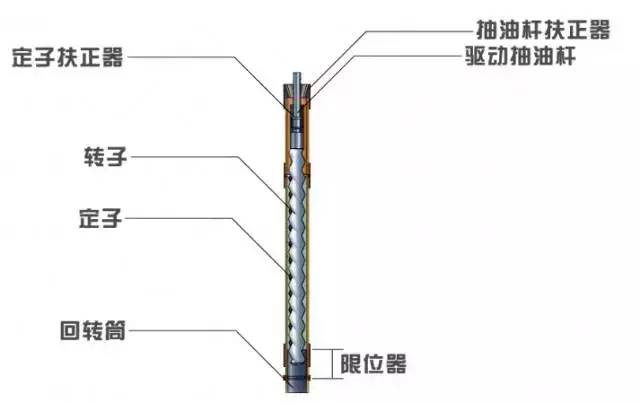

Submersible motor driven screw pump downhole system

Downhole system

Generally, it is mainly composed of stator, rotor, rotary cylinder, stopper, sucker rod, sucker rod centralizer, stator centralizer, liner, packer, anchor device, etc. The ground drive system consists of transmission system, transmission head and coupling assembly.

Submersible motor driven screw pump

Basically similar to the basic composition of electric submersible pump, all moving parts are underground. The underground pumping system is composed of submersible motor, gear reducer, protector, flexible shaft, submersible screw pump and suction port. The string accessories such as oil drain valve and pressure measuring valve and the ground system are the same as the electric submersible pump.

Other lifting technology types: hydraulic jet pump and gas lift

Hydraulic jet pump

Hydraulic jet pump is a special kind of hydraulic pump.

working principle

The jet pump converts the high-pressure potential energy of the power fluid into high-speed kinetic energy through the nozzle. In the throat, high-speed power fluid is mixed with low-speed liquid to exchange momentum. The kinetic energy is converted into static pressure through the diffusion tube, and the mixture is extracted to the ground.

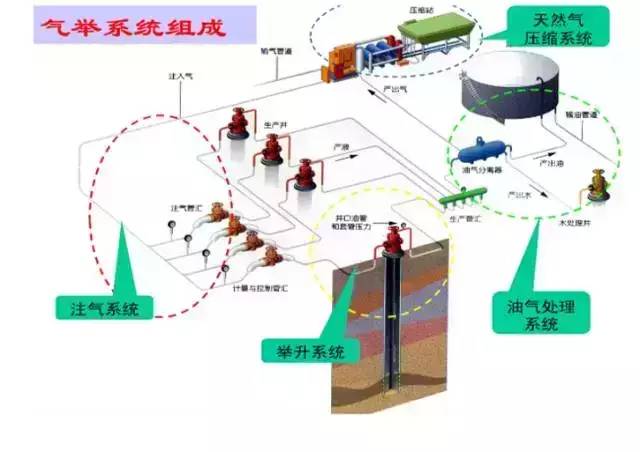

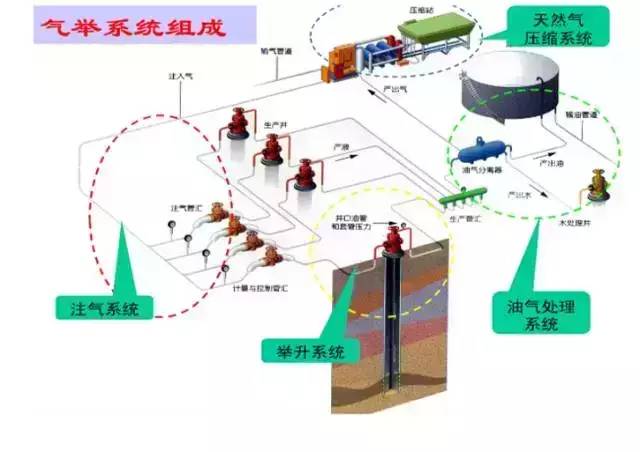

Gas lift production

Gas lift oil production refers to a kind of artificial lifting method that artificially injects high-pressure gas from the ground into the oil well that has stopped flowing to reduce the oil pressure gradient in the lifting pipe, and uses the energy of gas to lift the liquid.

working principle

Based on the principle of U-shaped pipe, high-pressure gas is injected into the annulus (reverse lift) or tubing (positive lift) of the oil casing on the ground to mix it with the formation fluid, reduce the density of the liquid column and the back pressure to the bottom of the well, establish the production pressure difference that lifts the liquid to the ground, and thus improve the oil well production.

Schematic diagram of gas lift system composition

螺杆泵的(of)傳動系統組成示意圖

螺杆泵的(of)傳動系統組成示意圖